Natural Floors

Above – cuckoo school, the floor before the floor.

We seldom care about where our feet rest. What are we walking on? are we grounded? are we connecting with mother earth? We are paying a huge price; by not allowing our bodies to be one with the constant healing that mother earth blesses us with. This disconnection causes an accumulation of stress, pain and disease.

At the other extreme, travelling through vernacular landscapes I come across such profound forms of human expression. As Charles Correa writes in his book “Vistara”, architecture is just a model of the relationship that man has with the cosmos. Man, trying to connect with the plants and animals around them, through art, expressing the admiration and deep connection with the beauty in them. The floors and walls talk about beautiful, souls, homes, families and communities – all four skins intact and connected with the cosmos. Man being fixed and the cosmos constantly changing.

This has been my journey so far, understanding local materials and techniques for natural floors. A lot of these images are a result of several failures, in projects and trials before projects. The hidden cost of experimentation is quite high and is usually covered by small gains from workshops. The cost of experimentation can be drastically reduced if there is a mutual sharing of lessons. www.Handmadearchtecture.org is a small attempt in that direction.

Earthen floors

Earthen floors are a delight to walk on, partially breathable (if allowed to breathe), great thermal mass and yes very well grounded!

Image source: earthfloors.co.uk

Image source: earthfloors.co.uk

Sleeping or sitting on an earthen floor is therapeutic. Walking barefoot on an earthen floor is a delight. India has a large tradition of several types of earthen floors, most are frequently maintained. A wide variety of earthen based final coats are applied on the earthen floor, from cow dung, cow urine, turmeric, tallow mixed with mud. Their purposes are multiple, and very much linked to our health, skin and the air we breathe.

Earthen floors are rougher in nature than a ceramic tile, this means that lesser skin is in contact with a floor surface while walking. The air gap between the floor and the skin acts as an insulating layer, thus cutting out extremes of temperatures. Its thus comfortable to use even in a peak summers day in a patio, or in a cold winters night indoors.

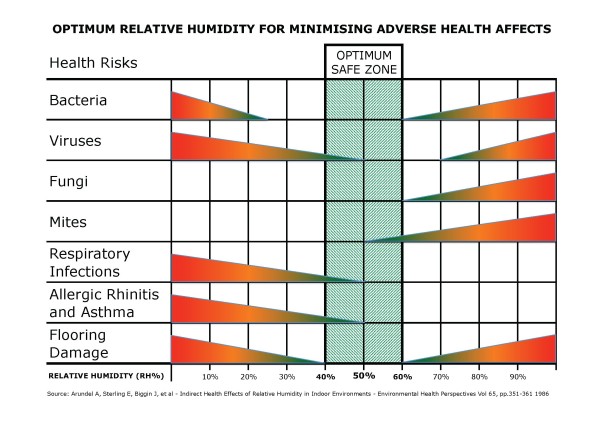

The floor breathes partially, so humidity is well regulated (if ventilation is controlled) and the home is naturally maintained in the optimum 40-60% RH Source: https://www.humiditydevices.co.uk/blogs/about-floors/15508913-health-risks-of-adverse-relative-humidity

Source: https://www.humiditydevices.co.uk/blogs/about-floors/15508913-health-risks-of-adverse-relative-humidity

I first learnt about earthen floors in my trips to Thiruttani (image below), Tamilnadu building Adityas Farmhouse, where I stayed overnight at my mason’s hut. Over the weekend, the family invited me to join them in refinishing their floor (something they do every month), with cow dung and cow urine mix along with ground turmeric and clay.

The traditional construction of the earthen floor and its layers vary from place to place, depending on the soil, level of insulation or thermal mass needed or the amount of moisture that can seep up from the ground. Observing the textures and colours of earthen floors and the effect it has on internal atmospheres has been an incredible journey so far.

Above: Earthen floor with a lime – oxide coat, in a vernacular kitchen, Seoni, India. Notice the rounding of edges and the clean transitions between lime and mud.

Below: a mud floor in a house in Kutchh, Gujrat. The softness of the floor is obtained through a mix of cow dung and mud, known to be antifungal. The floor base is of lime

Modern earthen floors differ as the regional nuances and variety have been reduced to a very engineered series of options. For a modern house, we are experimenting with an earthen floor on a wooden subfloor (so far). Here, the base layer is thick, 4″-6″ thick with a lot of aggregate, but well graded to form a solid base. Depending on the consistency of the soil-aggregate, this layer can either be tamped, vibrated or rolled over to reduce air content. This layer seldom has any fibre to avoid any capillary rise. This layer is the main structural layer which is sometimes laid over a vapour barrier/drainage layer, depending on the hydrology of the soil below. This, however, reduces the capacity of a floor to drain out and artificial drainage has to be added. Sometimes laid over rigid insulation in (colder climates) that increases chances of mould and growth of fungi. The traditional insulating mineral (pumice / volcanic rock, in case of the Mayan house of Mexico) does not have the problems faced in modern buildings, while at the same time responding to the ground conditions.

The levelling layer, by the name goes, is used to level out the base layer and protect the base layer (also called the base protection layer), it is usually between 1″-2″, to level out. This layer can contain some amount of fibre as it is simply laid out dry an needs some light tamping at most, the shrinkage has to be controlled. If there is little or no cracking, this layer can be used as the finish layer itself. It is normal for this layer to crack, and one has to pay a final coat on top of this layer.

Then there are a variety of sealants, hardeners, colours, water repellents that can be applied on the top after all drying is complete. Above in the images are common modern sealants, beeswax, linseed oil, casein.

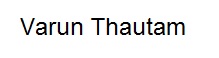

Working with earthen floors has been a wonderful avenue to learn more earth itself. A clear didactic for the use of earth in floors has already been developed and tested at several workshop settings. Below are the images of the workshop I held at Ameyatl.

Over the years, I have tried a variety of soil based floors, several in workshop settings, few in projects. There is little interest in this marvellous floor. One notable project was for the school of permaculture, Ameayatl at Cuernavaca, Mexico. Where we in a workshop setting did fractions of the base and base protection coat.

In a workshop setting, depending on the time available we can get into the following topics with sufficient detail. Every workshop brings out something new as it is an opportunity to share and learn from each other.

- Soil identification

- Soil mechanisms and principles of densification

- Fibres and additives; cement, lime, bitumen, resins, natural and synthetic products.

- Soil suitability for the base, base protection and finish coats/layers.

- Theoretical understanding of characteristics; mechanical, hydrous, thermophysical properties.

- Design guidelines: humidity, water, expansion joints, edges and transitions, wall bases, slopes and surfaces.

- Finishes; surface protection, maintenance.

As earthen floors take a long time to set, it’s hard to conduct a full earthen flooring process in a single workshop setting of 1 – 2 days, we need to revisit the same sample in 3 workshops organized one every month to understand the full process.

I am looking forward to projects and workshops where we can showcase the amazing possibilities of natural floors. We are working on earthen floor samples for Casa Bosque Real.

Lime Based Floors

Roman concrete, Cocciopesto, Opus Signinum, Dess, Quadad

There are a large variety of lime-based floors that I found at the lime-rich ruins of the Pyramids, Mayan houses and Aztec – Toltec ruins throughout my travels of Mexico. Photos and a deeper understanding of these floors will take a closer observation, deeper understanding and further research.

Masters of the technique in Mexico, have been the indigenous masons of Sierra Gorda, Queretaro. On the modern lime floors, Master Laurent Coquemont has been teaching lime based floors since 2015 in Mexico. Here is an example of his workshop – cocciopesto and Opus signinum. Over the dozen-odd workshops that I’ve attended, following him over the past four years, I am thankful to have gained a deeper understanding and grasp – granulometry, void to solid ratio, capillarity, rigidity, porosity, imperviousness and impermeability. He has developed a sound didactic for modern architects and engineers, simplifying the nuances of ancient Roman floors. He can be invited for a workshop if a project or group expresses interest.

The indigenous methods of fabrication of lime, construction or limestone kilns and the making of stone domes have been of special interest to me since 2015. I have been an apprentice to third generation master lime producer Jaime Ñonthe Salvador and his father. We have had several workshops organized to observe, document and understand the art of producing lime.

The cycle of lime and the various forms of lime, by tweaking the cycle has been a tremendous learning experience. Practical slaking methods were learnt over several workshops with Amel Kadic and Laurent Coquemont. We learnt about how different the use and applications of powdered lime, slaked lime (in paste), the water of lime can be obtained from the same limestone. The role of impurities and the consequence in the use of a method, storage methods and speed of carbonation; with several costly mistakes in the learning process. Identifying the purity of limestone and the methods of burning limestone in the indigenous and industrial methods in Mexico has been my constant documentation effort. I am looking for sources of all types of lime available in India. If you do know a lime source and have experience using the lime, please do let me know. Collectively, we can document and map them out.

Image below: slaking of lime in a workshop setting; Laurent Coquemont

Below are images of some modern Mexican factories, producing up to 1000 tonnes of lime every day. Note that the firing is not as complete, in the industrial processes (the core has not been burnt yet). While, in traditional methods, the quality of lime is far superior!

Lime and its chemical reactions with various materials such as: pozzolana, burnt brick, marmolina (lime stone dust, graded), tepetate (a type of silty – volcanic ash in Mexico), carbonate, silicate, aluminate, and magnesium-rich soils has been an exciting process of successful experimentation and implementation. We have been able to develop small applications, like bases of cisterns, bathtubs, Kitchen-tops, Shower bases and waterproofing of Vaults and domes.

While finishing with lime, the use and control of water in mixes has been a steady learning process. The amount of water has to be kept at the minimum, yet work-ability has to be achieved. The viscosity can be controlled with various additives (processes), using soap, casein, maize starch / Cellulose, egg white. The speed of drying is critical, the slower the mix dries, the better a finish is achieved as it allows more time for trowel action. Retarding can be done with the use of Soaps, Linseed oil and “baba de nopal”, a cactus flesh extract.

Above: Baba de nopal, for Casa Amealco.

Above are images of some different lime based floors in a workshop with Laurent Coquemont. Quadad, Dess, Cocciopesto are more kinds of lime floors. The origins of these floors can be traced to Morocco, Yemen, Rome. These while different in composition (lime source, granulometry of aggregates, additives, thickness etc), they are all lime based and are surprisingly similar in look and feel to the lime plasters we see in India – the Chettinad egg plaster, or to the lime plasters from Yucatan, Mexico – a waterproof stucco called “Chukum”. It feels as though a lot of the know-how comes from common ancient origins.

For the Casa Amealco, we went for a coccio-pesto base and lime stabilized earth based concrete mix for the floor to obtain a cost-effective sub-floor. (as taught by Maestro Coquemont). For Casa Naomin, too we tried a mud floor but failed to convince the clients, as they opted for a richer wooden floor.

Below are a series of images of Opus Signinum – A superb floor fit for the kings.

I am currently assimilating all the information gathered from dozens of workshops and years of apprenticeship opportunities from the masters. It will take me some more time to develop a clear didactic for architects and engineers. Any workshop would be incomplete without the help of local artisans. If anyone can connect us with vernacular wisdom, a workshop can be organized with a rich exchange of information.

If sufficient interest exists in a project/workshop. Experts such as Amel Kadic can be invited to hold a workshop on lime floors and Tadelakt. His finishes are literally out of the world, fit for the queen! See photos below. I take great pride in being his apprentice for the past 4 years. Every workshop with him is an opportunity to find profoundness in every aspect of building. As a guide, and a friend he has helped us greatly improve our quality of work, attitude and levels of professionalism.

It is always a delight to be able to achieve trowel and burnished stone finishes that are a delight to touch. Below are some images of handmade finishes that I have achieved personally.

Cement oxide floors

Masons in Thiruttani, while building Adityas farmhouse, taught me the traditional methods of red oxide flooring. At around the same time, I encountered an impressive document circulated in the office of my mentor, Chitra Vishwanath. This document by an unknown author, Sangeetha and Ramkumar tell a similar method to what I encountered at Thiruttani, with several variations.

Over the years, I have implemented several variations of the oxide flooring methods while learning a lot more from the impeccable floors at the home of architect Eduardo Obregon Peña in Mexico. The approach by this master is to simply lay a trowel based skim coat of 2-3 mm over a set concrete pour, however using a Resin based cementitious primer and adhesive before application. The traditional cement flooring in Mexico (done my masons in cities) is to finish off a pour with a large trowel, sometimes adding additives on the top surface while the cement is fresh and wet (before or after trowelling). Sometimes this floor is washed off with an acid which adds the handmade texture to the floor.

Commercial cement flooring is similar to laying a terrazzo floor with several wounds of machine brushing and polishing with an increasing grit.

We have successfully executed several oxide floors in my projects. Most recently in Casa Tlali in 2019.

Here in India, I am looking to reconnect with masons who can execute a traditional oxide floor. Over time, the local masters can be organized to develop a full workshop at a live project. I am not sufficiently skilled, nor well versed with the nuances of cement use, nor am I a big fan of these floors. Cement floors do not respire and lack all the finesse of earthen floors. However, they do provide a better alternative to ceramic floors for a cost-conscious client. They are also good where there is high traffic, heavy moving of furniture or rough use. Cement floors need low maintenance and are easy to fix.

Note: Cement floors should be avoided at all costs for spaces where seeds/livestock are stored!

Stone and Brick Floors

On another note, we have explored a series of stone floors for both indoor and outdoor use. For someone who doesn’t mind the dirt, and loves textures under their feet, these floors are incredibly durable and maintenance free.

Above: Stone floors in Darasuram temple, The multiple stone textures and patterns speak meaningfully of purpose, hierarchy and utility. The stone floors are absolutely watertight (and have been so for 6 centuries now) and they are perfectly inclined, set in a time base in intricating details, all for the purpose of water storage.

Stone floors are probably the most sustainable option as they last for centuries, if not millennia without the maintenance! We have tried to use local stone with local textures as much as possible in projects, as they are cost effective and the vernacular touch, situating every project in its cultural landscape.

Below: use of a local granite (Chappadi), in Bangalore for Prakruthi, a project we did in 2010. The rough hand dressed texture brings back childhood memories of sitting on temple floors and listening to Carnatic music 🙂

Below: Or Tandoor, Bethamcherla, Shahbad, Cudappah, used in projects such as Prakruthi, and Madilu, in Bangalore. Though these stones are from Andhra Pradesh, local talent is still available, is of high quality and very reliable. Bethamcherla is one of the most cost-effective stone still available and a painfully smooth finish is available for modern clients.

I find the trend towards smooth, shiny floors annoying. Smother floors are cold (literally and figuratively). I associate it with the sanitized environment of a hospital or a clean room. Like the Paimino Sanatorium by Aalto. Perhaps the advertising for the sale of harmful sanitizers and chemicals for the floor is to blame. Perhaps my women clients (like my mom and my grandmom), who believe a floor needs to be squeaky clean, and are behind household help to mop every nook and corner every day!

Common knowledge is that while fungus and viruses are harmful, some amount of bacteria is useful and perhaps necessary for our health. Over sanitizing environments is making children less-immune to the external world. Children crawling on floors is a chance for them to grow resilience. Unfortunately, this resilience is now being administered with a neverending number of vaccines.

Ceramic Tiles are unsustainable, (a mere thin printout) of a cold – pseudo texture that I find very hard to connect with. Clients go to the extent of demanding rectified tiles (with a zero mm gap), or tiles of larger dimensions such that the gaps are minimal. The moms’ reason that the gaps are where dust settles and that means maintenance and dirt.

See this painful Ad by dettol – https://www.youtube.com/watch?v=gIjV2ms2Qqs

I would demand two important properties on every floor – porosity and texture. Porosity allows humidity regulation, dust and bacteria. Texture adds grip, safety, touch and warmth.

Some of our clients are at the other extreme, who love the roughness of stone (inside and outside). At casa Macazaga, we skimmed stone off the floor of a nearby lake. The stone naturally excavated from sediments of rocks could be assembled into a very durable outdoor stone floor / Roadway / Patio.

Brick floors, on the other hand, have a high energy footprint. I do use a lot of brick floors as they have a great thermal mass and respire. This allows them to regulate humidity, absorb sound and heat. They contribute to a great indoor environment.

With the right details these floors last really long. Over time, the bricks smoothen out with use and adapt to the use, imprinting a memory of the life above it. I have seen 2oo year brick floors in Patzcuaro, Mexico where the streets and patios talk about all the activities it’s seen in its lifetime. Where have people frequently walked, stopped, sat or slept?

The arrangement of bricks in patterns is an exciting design process and can make every floor and space transitions unique and meaningful. Below is a brick floor for casa Amealco, where I worked out a flower pattern for a yoga shala at the request of the client. Brick tiles were cut and set in lime mortar. It has been a delight for the clients, they say it’s been a privilege to use the space.

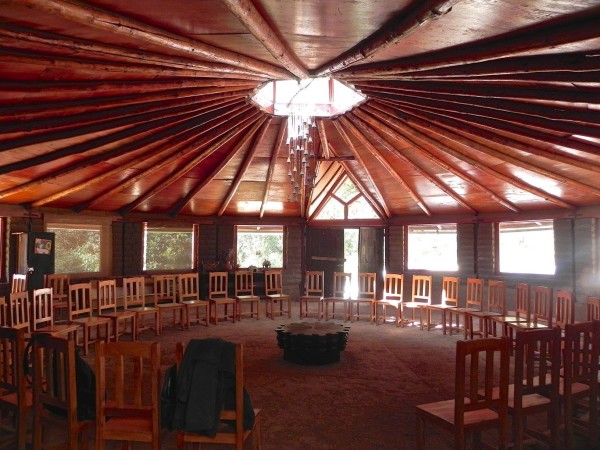

At Casa Daniel, we used brick floors for the outdoor patios and terraces. We also learnt to use brick tiles to create light staircases. The problem with brick floors is the chipping of edges if left exposed. Brick floors can be made smoother in nature with the right selection of brick / sealing a floor with oils and waxes. We have been experimenting with natural linseed oil, beeswax. This partially or totally seals the brick floor and will need a recoating every decade.

Wooden Floors

This is hands down, my all-time favourite floor. If the wood is sustainably harvested (one is planting and caring more than cutting). A great way of carbon sequestration indeed!

Thanks to excellent carpenters like Erick Jose and Paulino Rico, we have been using wooden floors and ceilings extensively in Mexico. Local Pinewood is cheap and easily available. However one has to understand the whole process of how and when (depending on moon cycles) and where (northern slope / southern slope) the wood is cut, rested, dried (sun-dried / oven dried / shade died), reformatted (split / hand-cut / machine cut), stacked (to control warp, bow, crook, kink, cup twist), treated (burnt, soaked, sealed, coated), joined, and finally finished.

The learning process has been immense, with more than 300 sq m of wooden floors in Casa Amealco, 25 sq m in casa Naomin, 150 sqm in Casa Daniel and 185 sq m in Casa Tlali. In each project, we have learnt and upped the quality and reduced the cost of flooring.

We closely look at every step, tying up with the right cutters, vendors, carpenters. Control of the whole process without omitting care at any step is critical in developing the right wooden floor that lasts.

Wood holds a special place in my design approach as the structural system itself becomes a flooring system. Here structure, pattern, colour, texture and thermal delight find a combined expression with minimum cost and effort.

Wood is an element that can be used to create harmony, as the kitchen, closets, handrails, stairs can all be united with the floor. The seamless design allows easier detailing, minimum transitions and hence harmony.

Wood is scarce in India as the forests have all given way to human urban survival, need and greed. While still a lot of our lands is healing from overuse, we have an incredible opportunity as a deprived community to restore our lands.

The affluence we see in modern materials, in my opinion, is the poorness of our souls, our families and our communities. Architecture is just a representation of ourselves with the cosmos. In spite of our cultural heritage, our spirituality and belief in scriptures, we are indeed poor here in India, heading the wrong direction.. while the west is already intuitively reconnecting with the cosmos and themselves.

I am looking to connect with clients here in India, who can give us opportunities to reconnect with the artisans, revive our traditional methods and help us continue our richness; be it an urban /rural setting.

Esta súper padre la página

Muchas gracias por compartir tus experiencias aquí documentadas!

Felicitaciones por tu trabajo!!!

Espero que pronto continúes en México trabajando