Rammed Earth Consulting, Puerta de Lobo, Queretaro, Mexico

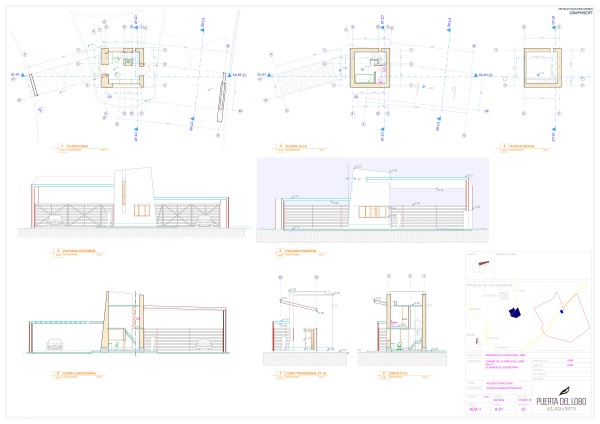

In April 2016 a prime developer of second homes/vineyard homes in Queretaro approached us for a consultancy on a unique project. The design they had in mind is seen in the drawing below. (The drawings are maintained at a low resolution for privacy).

Clear challenges were seen in the design from the start of the project

- The rammed earth walls did not have a hat / overhand / protection. This would not work for the periodic rainfall that Queretaro receives. The walls would degrade over time.

- The concrete slab was supported by the four earthen walls. (similar to the project by Mauricio Rocha – School of Plastic arts, Oaxaca). The volume of the walls would have to allow about 0.5% change in volume even after a month of setting. The rigidity of the concrete slab would mean challenges in detailing the joint between the concrete and Rammed earth. A flexible, yet waterproof member would be an ideal fit.

- The sheer volume of rammed earth (6m high, 60 cms thick) would mean a lot of shrinkages. The irregularity of form meant that there would be irregular shrinkage. Controlling of shrinkage will be the main challenge.

- The inclination of the rammed earth surface on the exterior would make it challenging to form.

- The developer/ designer insisted on the formwork having a texture (wooden planks of 10 cms or thinner, with a superficial variation of 5mm-10mm). Would pose a challenge, as the earth would not be hard enough to maintain the texture.

Even after several attempts at convincing the clients, there was no reconsideration of the above points. My task was limited to just developing the right mix, the formwork, and training of a team to execute the project.

Rammed earth was being seen as a concrete, though there are similarities. The understanding of Rammed earth is all about how different it is from Concrete.

Heres some photos of the process.

Here are a summary of lessons learned/taught.

- Rammed earth is a material that is soft, it cannot directly come into contact with something rigid. Rigid elements (concrete/steel) have a higher vibration and this will damage the softer material where forces are continued.

- Ramed earth breathes, it regulates a ton of moisture. Thus there has to be a continuity of moisture with any material that comes in contact with rammed earth. If not, there will be an accumulation of moisture at the joint / point of contact. This might be detrimental to rammed earth, or the impermeable/impervious material.

- Rammed earth sets slowly, it shrinks up to 2% in volume of the formwork. This shrinkage is accelerated initially, (0-5 days) then slows down.. but the shrinkage continues over a few months to a year (sometimes a couple of years). This change in volume means that any rigid element in contact with rammed earth will want to move with the shrinking rammed earth. All elements in contact with Rammed earth have to be flexible / allow space for shrinkage.

- The construction process should consider this shrinkage seriously, as old rammed earth cannot join with new rammed earth. All connected elements should shrink together. Walls should be designed to have separation/gaps that allow shrinkage.

- Rammed earth expands and shrinks daily (it is like a living thing) that absorbs moisture during the night and releases moisture during the day. This change in volume has to be considered, though small (0.01%).

- Rammed earth preserves wood and thus any ties inside rammed earth would ideally be of wood, rather than steel/concrete. Steel/Concrete is too rigid to tie Rammed earth.

- Steel has a severe modulus of thermal expansion as compared to rammed earth, thus the connections between steel and earth should allow for this relative movement.

- In the event of an earthquake, rammed earthworks as a monolith, distributing its forces throughout its mass. Thus even a 1 mpa wall would work better than a 5 mpa brick, in masonry.

- Because of its softness, rammed earth is not designed to take a point load. All loads should ideally be distributed along the wall.

More detailed analysis, with research material, photographs and results of various experiments can be understood in a workshop/classroom setting. It is extremely important to understand this grandmother of a material before considering its use in modern architecture.

All credits to the developer for the audacity to use the material in a modern format and successfully execute this expensive project.